Wireless and Integrable Digital X-Ray Detectors

Large size, high contrast detector for all-purpose radiography

Large size, high contrast detector for all-purpose radiography

Applications

A static digital detector array, DXR500L allows for fast and easy defect detection by utilizing Endurance™ technology, developed to reduce radiation wear out and to maximise cost savings in a production environment.

A static digital detector array, DXR500L allows for fast and easy defect detection by utilizing Endurance™ technology, developed to reduce radiation wear out and to maximise cost savings in a production environment.

Applications

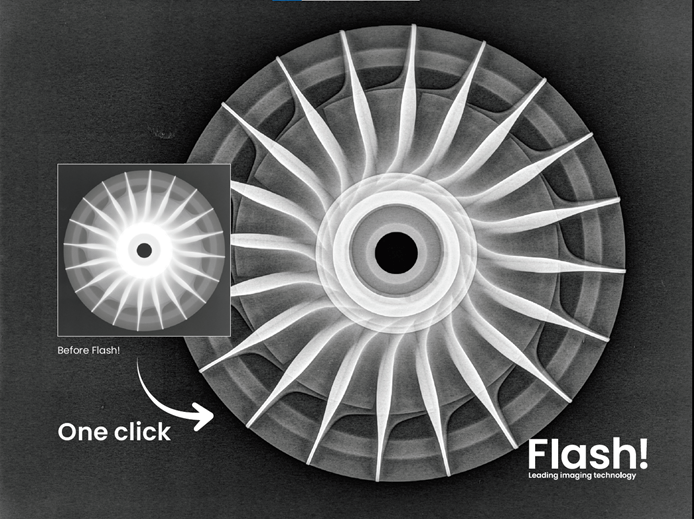

With one-click image processing, Flash! works as a layer on top of the image, without altering the raw data or the measurements made.

* Digital imaging and communication in non-destructive evaluation: a global standard for handling, sharing, storing and transmitting information between DICONDE-compliant systems.